The day after Christmas seems a little late to post another update on my garden path, but honestly, it’s the first chance I’ve had. I get buried in my glass work beginning October and don’t allow much time for anything else except my grandkids’ sports activities.

At the end of my last post I was getting ready to add salvaged barrel rings in my garden. I was pretty sure the barrel rings would each take a whole bag of 60 lb. concrete mix. Knowing I wouldn’t be able to stir up that much concrete by myself, even if I mixed it in three small batches, I asked my husband if he’d help me stir and this is the answer I got …

I should have asked a lot sooner, lol. His help was still needed and appreciated because I couldn’t lift the heavy bags to pour them in. He also kept the mixer going and handed me buckets of mixed concrete as I needed it so I wouldn’t have to keep getting up and down off the ground.

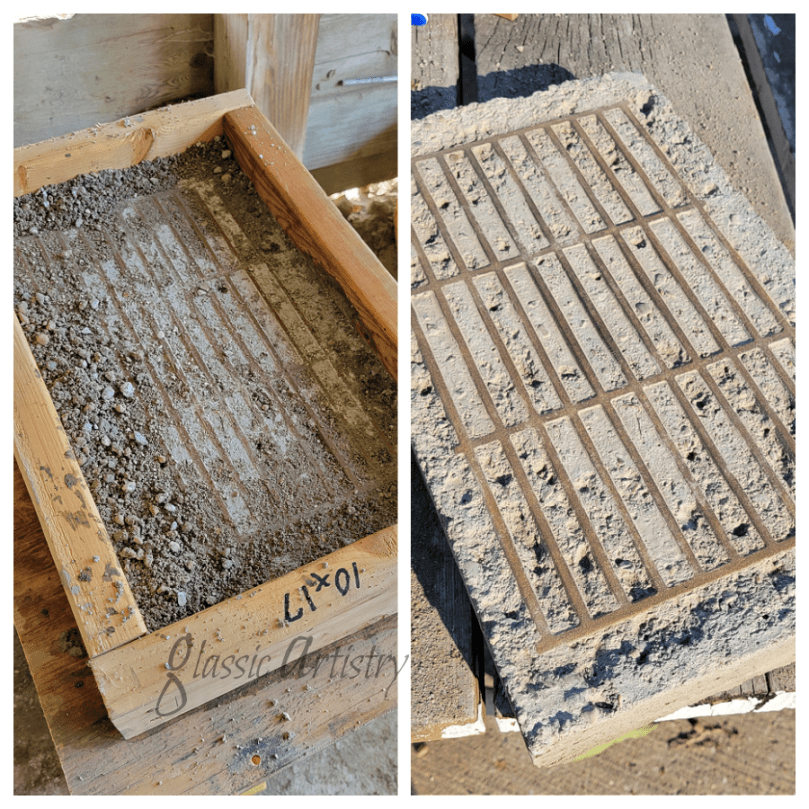

A barrel ring isn’t very high so we stacked two together for added height and attached them together with scraps of steel and self tapping screws. The protruding screw ends on the outside of the rim were cut off.

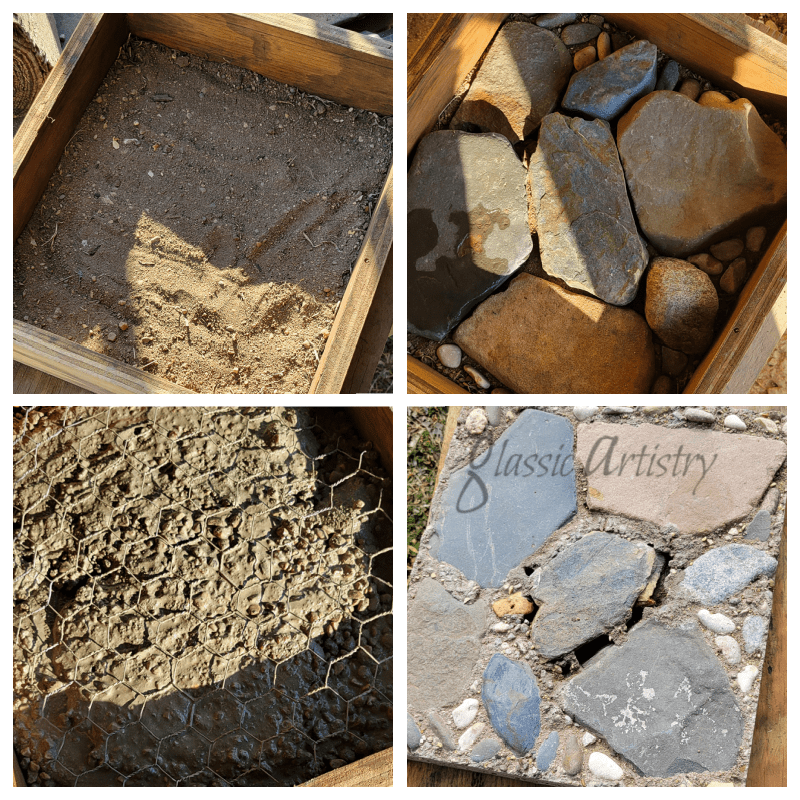

Circles were dug in the garden to accommodate half the depth of the joined rings. The ground was tamped down well before sprinkling in a thin layer of sand, then tamped again.

Earlier I had gathered a bunch of rocks I thought would work well. They couldn’t be higher than the ring and most had at least one flat side. To be more prepared, spare rings were laid next to the ones to be poured and filled with an arrangement of rocks. I laid out more than enough rocks so I had quick options while filling the rings.

The prep work for this project took the most time. Once everything was in place and the concrete mixed, it went rather quickly, especially with the extra pair of hands.

I started with a thin layer of mixed concrete over the sand. Staying a little ways away from the edge of the ring, rocks were added a few at a time, trying to keep level with the top edge of the ring as best I could. With a large spoon I scooped concrete from a bucket and filled in around the rocks as I went, jiggling the rocks a bit to settle it in, until the ring was filled. With a gloved hand, I wiped a thin skim layer of concrete over all to fill in any little holes or spaces.

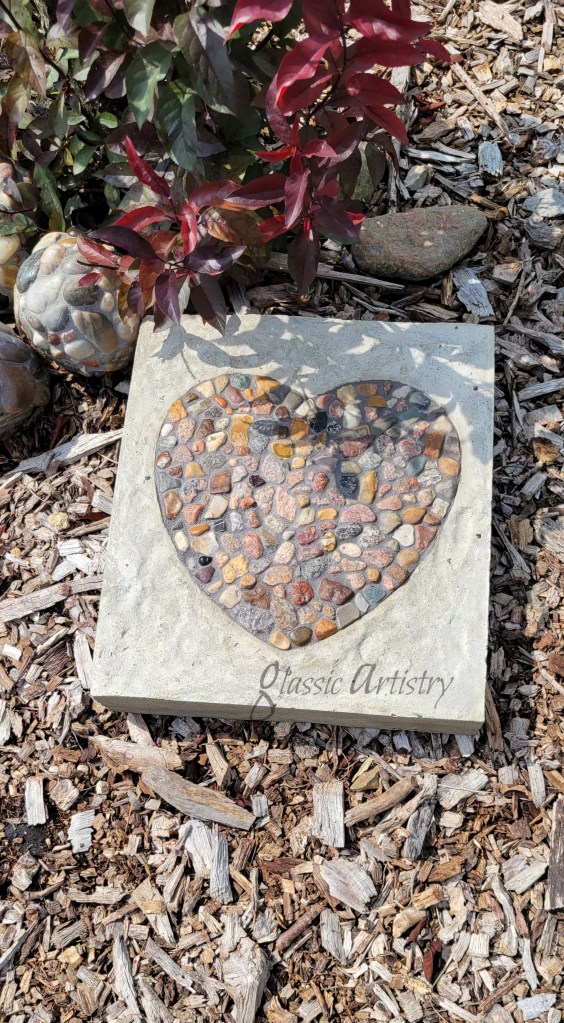

After the stones dried for about an hour, I wiped them down lightly with a wet rag to smooth the concrete. At this point I could make out the shape and color of the rocks under the concrete.

Being late in the season and with freezing temps expected overnight, the stones were covered with a tarp to hold in the heat.

Early the following morning, I washed the stones lightly again, this time using a rag and a plastic bristled scrub brush before recovering them. Later in the day they were given a final wash and rinse. Mulch was pushed back up around them to see how they looked. I thought they looked great, just what I envisioned.

Even though it’s probably not needed, I decided to keep them covered with a tarp to protect them from ice for their first winter. I guess it will remain to be seen how they look in the spring.

As you can see in one of the pictures above, a large cast iron ring and concrete circle have made it to the garden too. They’re not buried in or necessarily where they will stay. I just had the opportunity to get them moved to the garden and I took it.

I have a few months now to think over my next steps. I have a feeling the new concrete mixer may help me step up my game a little.

For now, I hope you all had a wonderful Christmas and wish you much love and happiness in the New Year!